Description

Description

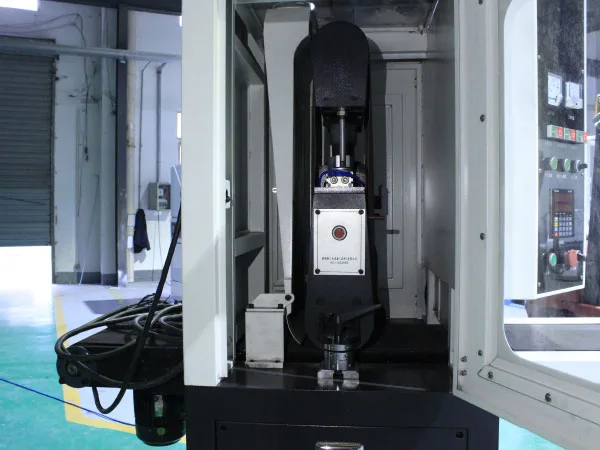

The LSP series includes multiple forms by applying to wide abrasive belt and universal brush, which can be used independently or compositely. The equipment can realize all-round and uniform removal of molten slag burrs formed by laser cutting, shearing cutting, plasma cutting, flame cutting, punching cutting, machining and so on. It is suitable for surface pre-grinding, deburring of holes, edges and rounded corners, and surface drawing. No damage to burr can be achieved for the film board and galvanized sheet.

Equipment Configuration:

- Working width: 600mm, 800mm, 1000mm, 1300mm

- Workpiece feeding mode: belt feeding, vacuum negative pressure adsorption is more than 50mm * 50mm

- Feeding speed: 0.5m/min – 8m/min variable frequency electrodeless speed regulation.

- Abrasive belt linear speed: 12m/s – 20m/s optional

- Rolling brush rotation speed: 600r/min – 1500r/min variable frequency electrodeless speed regulation

- Rolling brush revolution speed: 5r/min – 30r/min variable frequency infinitely variable speed.

- Equipment processing thickness opening range: 0mm – 100mm

- CNC PLC centralized control of the whole machine.

- Treatment of grinding dust by matching industrial pulse vacuum cleaner